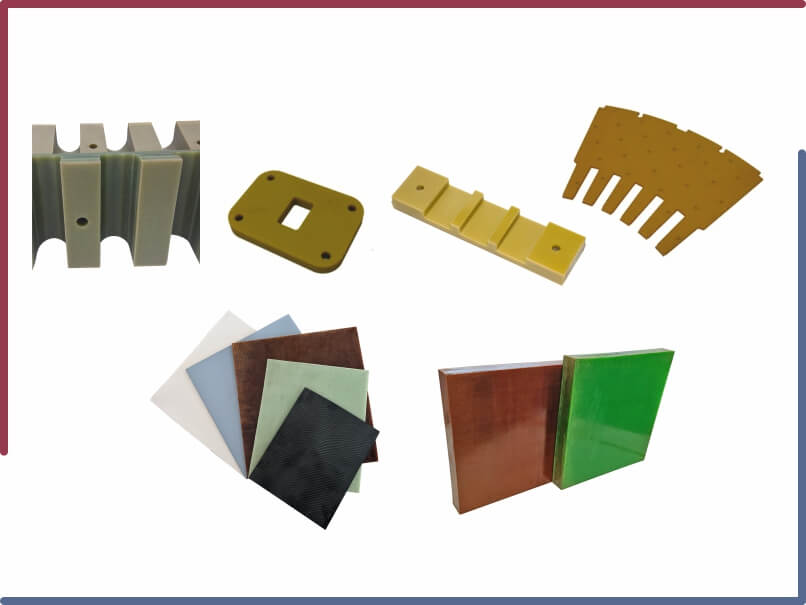

At ORIONE COMPOSITES & ENGINEERING PVT. LTD., we have modern State of the Art facilities for Developing and Manufacturing Composite / FRP Products used in Railways, Electrical Insulation, Water Treatment Plants, Chemical Storage, Heavy Engineering Industries, R&D Organisations, Mining, Oil Exploration, Fisheries, Airports etc.

We are an ISO 9001:2015 certified Company with a well-equipped Laboratory for testing of Raw Material and Finished Products for Physical, Mechanical, Electrical and Fire Worthiness Properties.

Our Team is well experienced and qualified in Product Development, Process Control, Production, Quality, Marketing and other functions to work continuously towards achieving excellence with respect to Innovation, Quality Standards and Customer Satisfaction.

To be one among the preferred manufacturer and supplier of Composite / FRP & Engineered Products.

Deliver sustainable results through our business to all the related Stakeholders.

Railways

Process Plants

Chemical Storage & Transportation

Ship Building & Offshore

Mining

Renewable Energy

Power Generation, Oil & Gas Plants

Telecommunication

R & D Organisations